Servo motors are perfect for systems requiring great performance because of their ability to precisely control position, speed, and torque. However, controlling servo motors is a complex process, and various control methods are employed to achieve optimal performance based on specific requirements.

In this article, we will explore five common control methods for servo motors, discussing their features, advantages, and best-use scenarios. We will also include some charts to help you understand the differences between these control methods more clearly.

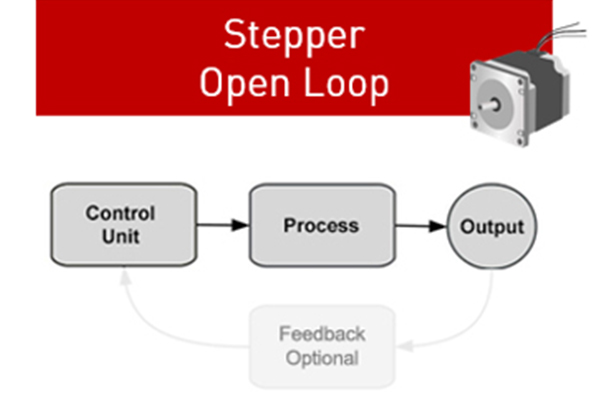

Open-Loop Control

Open-loop control is the simplest form of servo motor control. In this system, the motor receives commands based on pre-set values, such as speed, position, or torque, without any feedback mechanism. To carry out a task, the controller signals the servo motor, which reacts in accordance with this input.

In open-loop control, there is no continuous monitoring of the motor’s performance. Therefore, if there are changes in the system or disturbances (like variations in load or friction), the motor may not be able to adjust accordingly.

Features and Benefits

- Simplicity: Open-loop control systems are straightforward and easy to implement, as they do not require feedback sensors or complex algorithms.

- Cost-effective: Because there is no need for additional sensors, the cost of the system is lower compared to closed-loop systems.

- Suitable for low-demand applications: Open-loop control works well in applications where precision is not critical, and external disturbances are minimal.

Limitations

- No feedback: The biggest drawback of open-loop control is that it does not compensate for errors in position, speed, or torque.

- Inconsistent performance: In cases where there are changes in load or external forces, the motor may fail to perform as expected.

Use Cases

- Small robotics or automation systems.

- Applications with low precision requirements.

- Hobby projects or educational setups.

| Control Type | System Complexity | Cost | Position Accuracy | Feedback Used |

| Open-Loop Control | Low | Low | Low | No |

| Closed-Loop Control | High | High | High | Yes |

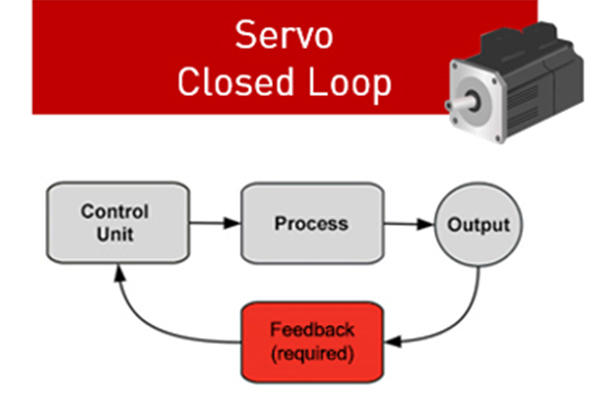

Closed-Loop Control (Feedback Control)

A more sophisticated technique for managing servo motors is closed-loop control, sometimes referred to as feedback control. In a closed-loop system, feedback devices such as encoders, resolvers, or tachometers are used to monitor the motor’s position, speed, or torque.

Based on the difference, called the error signal, the controller adjusts the motor’s performance in real-time to achieve the desired output.

This continuous feedback mechanism ensures that the motor adjusts itself to maintain accurate position, speed, and torque.

Features and Benefits

- Precision: Closed-loop systems offer high accuracy and can compensate for variations in load, friction, and environmental conditions.

- Adaptability: Feedback allows the system to adjust for changes in the load or any unexpected disturbances, making the system more robust.

- High Efficiency: Closed-loop control minimizes energy waste, as the motor can adjust its behavior to match the needs of the system.

Limitations

- Complexity: Closed-loop control systems require additional components like encoders and controllers, making them more complex and costly than open-loop systems.

- Higher cost: Due to the need for feedback mechanisms and more sophisticated controllers, closed-loop control systems are more expensive.

Use Cases

- Industrial automation systems.

- CNC machines and robotics.

- Applications like medical equipment demand a high level of precision.

| Parameter | Open-Loop Control | Closed-Loop Control |

| Feedback Mechanism | None | Continuous Feedback |

| Precision | Low | High |

| System Complexity | Simple | Complex |

| Cost | Low | High |

| Suitable For | Low-demand tasks | High-precision tasks |

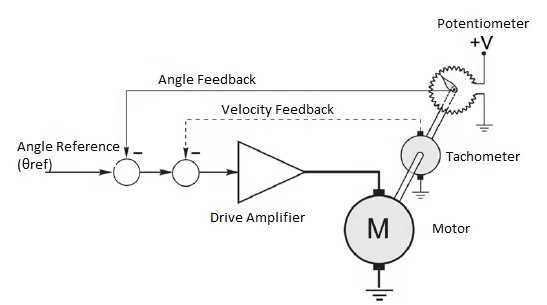

Position Control

Position control focuses on accurately controlling the position of a servo motor. In this method, the controller sends a signal to the motor to move to a specific position, and the feedback mechanism ensures that the motor reaches and holds that position. Applications like robots and CNC machinery that demand exact placement depend heavily on this system.

In position control, the controller continuously monitors the position of the motor and adjusts the input signal to correct any deviation from the target position. This method is often implemented in combination with closed-loop control for improved accuracy.

Features and Benefits

- High Precision: Provides highly accurate positioning, making it ideal for robotics, automated manufacturing, and medical applications.

- Real-Time Adjustment: The motor can adjust continuously to reach the exact position even in the face of load changes or disturbances.

- Versatility: Works well in applications that require specific angular or linear positioning.

Limitations

- Complex Setup: Requires precise feedback devices (such as encoders) and algorithms to control motor movement accurately.

- Higher Cost: The system is more costly since it requires more sensors and controls.

Use Cases

- CNC machines and 3D printers.

- Robotic arms and automated pick-and-place systems.

- Precision manufacturing processes.

| Control Method | Primary Focus | Precision | Speed Control | Load Compensation |

| Position Control | Position Accuracy | High | Limited | High |

| Speed Control | Speed Regulation | Moderate | High | Moderate |

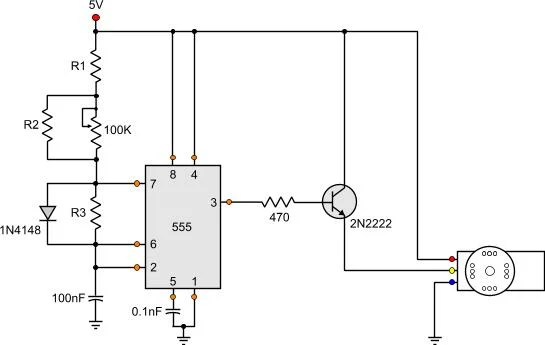

Speed Control

In speed control, the motor’s speed is adjusted by changing the input signal to maintain a constant speed despite variations in load or other disturbances. Speed control is critical for applications where maintaining a consistent speed is more important than position accuracy.

In many cases, speed control is combined with other control methods, such as closed-loop control, to ensure that the motor maintains the desired speed and adjusts for load variations.

Features and Benefits

- Consistency: Speed control ensures that the motor runs at a constant speed, even when the load fluctuates.

- Efficiency: Reduces power consumption in applications where maintaining speed is more critical than position accuracy.

- Simplicity: It is simpler to implement than position control, making it more cost-effective in certain applications.

Limitations

- Lack of Positioning Accuracy: Speed control is focused on maintaining speed, not on the motor’s position, making it less suitable for precision applications.

- Less Robust: Can struggle to maintain performance in the face of significant external disturbances, such as heavy load changes.

Use Cases

- Conveyor belts, fans, and pumps.

- Applications where continuous motion without positional accuracy is required.

- HVAC systems and low-load industrial applications.

| Control Method | Primary Focus | Precision | Efficiency | Application Type |

| Speed Control | Speed Regulation | Moderate | High | Conveyors, Fans |

| Torque Control | Torque Regulation | High | Moderate | Load-sensitive tasks |

Torque Control

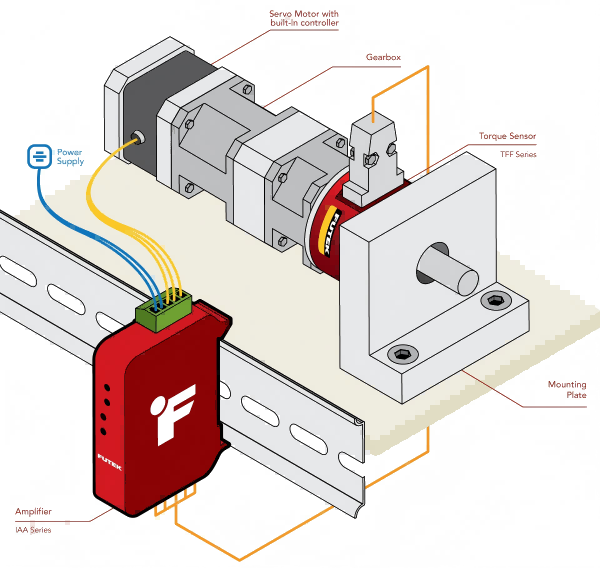

Torque control focuses on regulating the torque output of a servo motor. In this method, the motor adjusts its current to maintain a specific torque, regardless of speed or position. Torque control is essential for applications where consistent force or torque is more important than maintaining a specific speed or position.

Torque control is commonly used in testing machines, presses, and systems requiring precise force control.

Features and Benefits

- Force Control: Ideal for applications requiring precise control of force, such as in material testing or manufacturing processes.

- Load Sensitivity: The motor can adapt to varying loads by adjusting the torque output, ensuring consistent performance.

- Flexibility: Suitable for applications where speed or position control is not as important as the force exerted.

Limitations

- Complex Setup: Requires accurate torque sensing and sophisticated controllers to regulate torque effectively.

- Lower Precision: While it excels in torque control, it is less effective for applications that require high precision in position or speed.

Use Cases

- Test benches, material testing machines, and presses.

- Robotic arms require force feedback.

- Automated assembly lines that need precise force application.

| Control Method | Primary Focus | Precision | Force Control | Suitable For |

| Torque Control | Torque Regulation | Moderate | High | Material testing |

| Position Control | Position Accuracy | High | Low | Robotics, CNC |

The particular requirements of your application play a major role in determining the best control strategy for a servo motor. Whether you are seeking precision in position, consistent speed, or exact torque control, each method offers distinct advantages and trade-offs. For your system to operate as efficiently and effectively as possible, servo motor manufacturers need to comprehend the distinctions between these control techniques.