They are essential for high-performance systems because they offer exact control over torque, speed, and position. However, like any machinery, servo motors can fail over time, often disrupting operations and incurring significant costs.

The motor’s operational life can be increased, hazards can be reduced, and reliability can be enhanced by comprehending the underlying reasons of these failures. This article explores six major factors contributing to servo motor failure, with insights specific to AC and DC servo motors.

Overheating

How it Happens:

- Excessive Current Draw: High loads or improper tuning of servo drives can lead to excessive current draw, overheating the motor windings.

- Inadequate Cooling: Dust accumulation or blocked ventilation in cooling systems can impede heat dissipation.

- High Ambient Temperature: Operating the motor in environments with extreme temperatures exacerbates heat-related issues.

Effects on Motors:

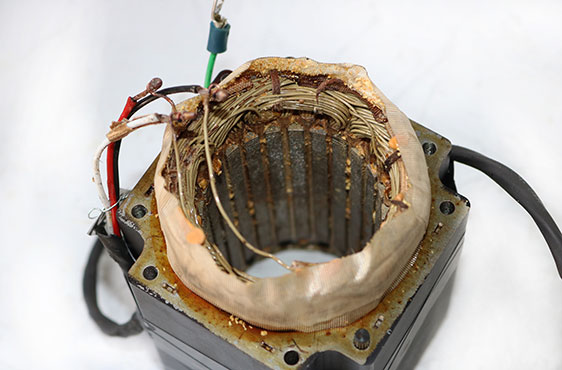

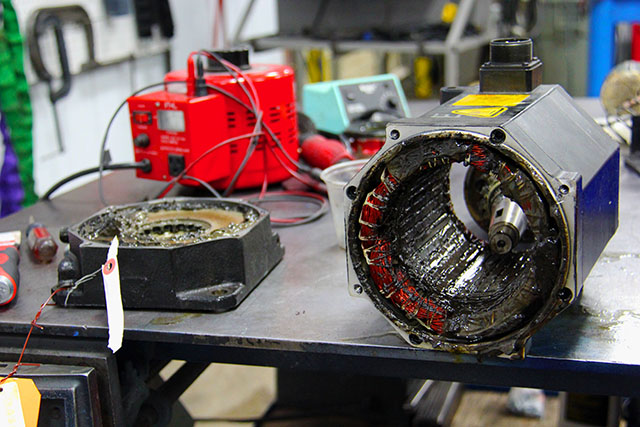

- AC Servo Motors: Overheating can cause insulation breakdown in stator windings, reducing the motor’s efficiency and eventually leading to winding failure.

- DC Servo Motors: Brushes and commutators are particularly susceptible to heat, causing accelerated wear and performance degradation.

Prevention:

- Regularly inspect and clean ventilation paths.

- Monitor motor temperature using built-in sensors or external thermocouples.

- Ensure proper load distribution and avoid overloading.

Electrical Issues

How it Happens:

- Voltage Spikes: Fluctuations in power supply can damage motor components.

- Phase Imbalance: Uneven power distribution across phases can cause stress on AC servo motors.

- Poor Connections: Loose or corroded terminals increase resistance, leading to overheating and arcing.

Effects on Motors:

- AC Servo Motors: Phase imbalance or voltage spikes can damage the drive circuitry and motor windings.

- DC Servo Motors: Incorrect polarity or poor connections can cause sparking at the commutator, accelerating wear.

Prevention:

- Install surge protectors and voltage stabilizers.

- Regularly check and tighten electrical connections.

- Ensure balanced loads in multi-phase systems.

Mechanical Wear and Tear

How it Happens:

- Bearing Failure: Bearings degrade due to contamination, misalignment, or lack of lubrication.

- Shaft Misalignment: The motor and related equipment may vibrate and wear down as a result of improper coupling alignment.

- Rotor Imbalance: Uneven weight distribution on the rotor creates additional strain.

Effects on Motors:

- AC Servo Motors: Vibration and noise indicate potential bearing or rotor issues.

- DC Servo Motors: Wear and tear on brushes and commutators are common due to constant contact during operation.

Prevention:

- Implement a proactive maintenance schedule for bearings and couplings.

- Perform periodic vibration analysis to detect rotor imbalance or misalignment.

- Replace worn-out brushes and commutators promptly.

Contamination

How it Happens:

- Dust and Dirt: Ingress of dust particles can damage internal components.

- Moisture: Humidity and water exposure cause corrosion of metallic parts.

- Chemical Exposure: Industrial environments with corrosive chemicals can degrade motor parts.

Effects on Motors:

- AC Servo Motors: Contaminants can interfere with the stator and rotor interactions, reducing performance.

- DC Servo Motors: Brushes and commutators are particularly vulnerable to contamination, leading to irregular current flow.

Prevention:

- Use motors with IP-rated enclosures suited to the environment.

- Install filters or seals to prevent contaminants from entering.

- Store motors in clean, dry areas when not in use.

Improper Installation and Alignment

How it Happens:

- Misalignment During Setup: Poor alignment of motor shafts and couplings leads to mechanical stress.

- Incorrect Mounting: Loose or uneven mounting surfaces create vibration.

- Improper Load Matching: Connecting a motor to an incompatible load results in excessive strain.

Effects on Motors:

- AC Servo Motors: Misalignment causes vibrations that can damage bearings and reduce motor life.

- DC Servo Motors: Improper installation increases the risk of brush misalignment and arcing.

Prevention:

- Follow manufacturer-recommended installation guidelines.

- Use precision alignment tools during setup.

- Ensure the load matches the motor’s torque and speed ratings.

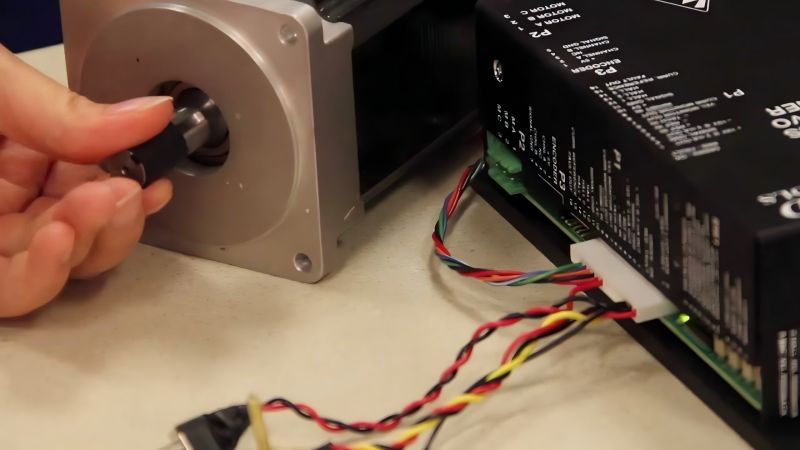

Drive and Control System Issues

How it Happens:

- Incorrect Tuning: Poorly configured PID (Proportional, Integral, Derivative) parameters in the drive system lead to instability.

- Faulty Feedback Mechanisms: Damaged encoders or sensors disrupt closed-loop control.

- Drive Compatibility: Using mismatched drives and motors can cause inefficient operation or failure.

Effects on Motors:

- AC Servo Motors: Faulty feedback disrupts smooth operation and can lead to position errors.

- DC Servo Motors: Inconsistent drive control results in irregular torque and speed.

Prevention:

- Regularly calibrate encoders and feedback systems.

- Ensure proper drive-motor compatibility.

- Update drive firmware and software to the latest versions.

Comparison of Failure Factors: AC vs. DC Servo Motors

| Factor | AC Servo Motors | DC Servo Motors |

| Overheating | Insulation damage in windings | Brush and commutator wear |

| Electrical Issues | Phase imbalance, drive circuit damage | Sparking, commutator degradation |

| Mechanical Wear | Bearing and rotor damage | Brush wear, commutator pitting |

| Contamination | Impacts stator-rotor performance | Brush and commutator damage due to dust |

| Installation Issues | Vibration from misalignment | Increased arcing due to brush misalignment |

| Control System Problems | Position errors from faulty encoders | Irregular torque and speed from poor control tuning |

Visualizing Common Failure Modes

Below is a sample chart showcasing the frequency of failure factors for AC and DC servo motors based on industry observations:

Failure Frequency Chart

+———————+———————+———————+

| Failure Factor | AC Servo Motors (%)| DC Servo Motors (%) |

+———————+———————+———————+

| Overheating | 25% | 30% |

| Electrical Issues | 20% | 15% |

| Mechanical Wear | 30% | 35% |

| Contamination | 10% | 10% |

| Installation Issues | 10% | 5% |

| Control Issues | 5% | 5% |

+———————+———————+———————+

Pie Chart Representation

I’ll create a pie chart to visualize these data points for better understanding.

Best Practices to Avoid Servo Motor Failures

- Implement Predictive Maintenance: Use tools like vibration analysis and thermography to detect issues before failure occurs.

- Adopt Environmental Safeguards: Choose motors with appropriate protection ratings and maintain clean operating conditions.

- Regularly Train Staff: Equip operators and maintenance teams with knowledge on proper motor handling and troubleshooting.

- Monitor Motor Parameters: Continuously track parameters like temperature, current, and speed to identify anomalies.

Servo motor failures can be minimized by addressing the six major factors: overheating, electrical issues, mechanical wear, contamination, improper installation, and drive system problems. Whether you use AC servo motors for their precise control or DC servo motors for their cost-effectiveness, proactive measures and regular maintenance are essential for optimal performance and longevity. As a reputable servo motor manufacturer, Gian Transmission ensures access to high-quality motors and expert guidance, which further enhances reliability and minimizes the risk of failure.