In most cases, stepper drivers are designed to control a single motor, with one set of output terminals per motor. However, with certain configurations and considerations, it is possible to run two stepper motors from a single driver. The possibility of this configuration primarily depends on the following factors:

- Motor Type and Rating: Both motors should have the same specifications, especially in terms of current rating, voltage, and winding configuration. Mixing motors with different ratings could lead to imbalance, overheating, or damage to the driver.

- Driver Capabilities: Some specialized stepper drivers, particularly those designed for multi-axis systems or multi-phase motors, allow you to control multiple motors from a single driver. Nonetheless, these drivers need to be able to supply both motors with adequate current. It’s essential to verify whether the driver can support the combined current requirement of both motors.

- Wiring Configuration: To run two stepper motors from a single driver, the motors need to be connected in a parallel or series configuration, depending on the specific type of driver and the motor characteristics.

Can Two Stepper Motors Be Controlled by One Driver?

Yes, but only in specific circumstances and after a lot of important considerations. There are two main scenarios where you might consider running two stepper motors from a single driver:

- Same Type and Size of Motors (Series Configuration): If the two motors are identical in specifications (voltage, current, coil resistance), they can be connected in a series configuration, meaning that the two motors share the same power and current resources from the driver. This is the simplest way to control multiple motors using a single driver.

- Same Type of Motors with Independent Control: Some advanced stepper drivers can drive two motors independently (for example, by using two separate output channels). In this case, each motor operates as if it has its own driver, but both are controlled by the same microcontroller or controller unit.

How to Run Two Stepper Motors from the Same Driver?

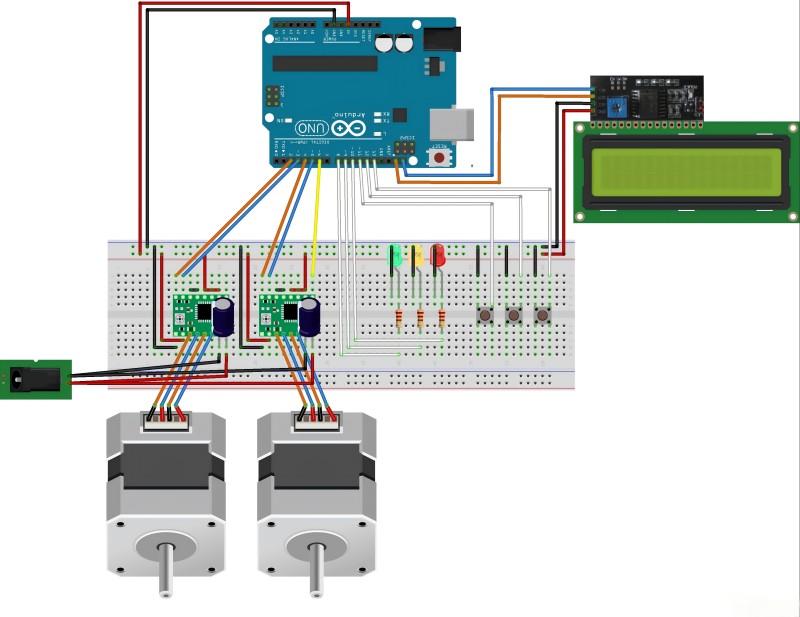

If your stepper driver and motors are compatible, here are the steps to run two motors from a single driver:

1. Check the Motor Ratings: Ensure that the two motors have the same specifications—voltage, current rating, and winding configuration. If they differ, running them together could cause uneven behavior.

2. Choose the Correct Wiring Setup:

- For parallel wiring, connect the windings of both motors together at each terminal (A+ to A+, A- to A-, and similarly for the B winding). Verify that the driver’s rated output is not exceeded by the overall current draw.

- For series wiring, connect the terminals in series, ensuring the current through both motors is equal. Be mindful that voltage distribution between the motors might not be equal, leading to potentially uneven motor behavior.

3. Verify Driver Capacity: Ensure the stepper driver is rated to handle the total current needed for both motors. If the current draw exceeds the driver’s capacity, it could overheat, trip, or even cause permanent damage.

4. Set Current Limiting: If your driver has adjustable current limiting, set it to half the rated current per motor (in the case of parallel wiring) to avoid overloading the driver. For series wiring, ensure the total current matches the driver’s rated output.

5. Test the Setup: Before running the motors in a full application, do a test run to ensure that both motors are running correctly, without overheating or stuttering. Check if both motors are synchronized and functioning smoothly.

Considerations for Running Two Motors from One Driver

Motor Specifications

Whether the two stepper motors have the same specifications is the first and most crucial consideration. Stepper motors are rated for specific voltages, currents, and resistance values. When running two motors from one driver, these specifications must be the same for both motors.

- Voltage and Current: Stepper motors generally come in two voltage ratings: one for the holding voltage and one for the operating voltage. If you connect two motors to a single driver, you’ll need to ensure that both motors can operate within the same voltage and current parameters. One motor may get excessive current if the motors are misaligned, which could cause overheating and possible damage.

- Coil Configuration: If the motors are bipolar, both need to have the same coil configuration (same number of windings, same resistance). Similarly, unipolar motors must have identical wiring and coil taps.

If the two motors have different specifications, running them on the same driver will create an imbalance and could potentially damage one or both motors. Therefore, it is critical that both motors are of the same type and rating to ensure that the system operates correctly.

Wiring Configuration

The way the motors are wired is crucial. For two motors to be driven from a single driver, they can typically be connected in either a series or parallel configuration, depending on the type of driver and motors:

- Series Configuration: In this setup, the two motors are connected in series, meaning that the current flows through one motor and then into the second motor. The motors must have the same current and voltage ratings in order for this arrangement to work. In a series setup, the driver sends the same current to both motors, but the total voltage required to drive the motors will be the sum of the individual voltages of each motor.

- Parallel Configuration: In this setup, the motors share the same voltage, but the current is split between the two motors. Each coil of the motors will be connected in parallel, so both motors will receive the same voltage, and the driver will provide the required current to drive both motors. Parallel wiring may require a driver capable of supplying higher current levels since the combined current requirement for two motors will be higher.

Driver Capability

Not all stepper motor drivers are capable of handling two motors at the same time. Many drivers are designed to control one motor only, and attempting to run two motors could damage the driver.

Some advanced stepper drivers, such as those used in multi-axis CNC machines, 3D printers, or robotics, are designed to drive two motors independently or in tandem. These drivers have separate output channels for each motor, which allows each motor to be controlled with its own set of current and pulse signals. This makes it possible to control each motor separately, even though both motors are powered by the same driver.

Microstepping and Synchronization

Running two motors from the same driver in a synchronized manner can be challenging, especially if you are using microstepping to achieve smoother motion. Both motors must be able to perform the same number of microsteps per full step to maintain synchronization, and the driver must support microstepping for both motors.

Additionally, the motors must be mechanically coupled (e.g., via a gear system or a shaft coupling) to ensure they move together in a coordinated fashion. Without proper synchronization, the motors could become misaligned, leading to errors in positioning and potential mechanical damage.

Practical Applications of Running Two Motors from One Driver

In practical applications, running two stepper motors from the same driver is more common in simpler systems, where the motors are performing identical tasks or movements. Some potential use cases include:

- Dual-Axis Control: In machines where two motors control different axes but perform the same movements (for example, two motors controlling the X and Y axes of a 2D CNC machine or 3D printer), using a single driver may simplify wiring and reduce the need for multiple drivers.

- Shared Loads: In scenarios where two motors are used to share the load, such as in a system where both motors move a single stage or mechanism, running them off the same driver ensures that both motors receive equal current and perform similar tasks.

However, for applications that require independent control of two motors (such as for controlling different axes of movement), separate drivers for each motor are usually the better solution.

Conclusion

While it is technically possible to run two stepper motors from the same driver, it is only feasible under specific conditions. The motors must be identical in specifications, and the driver must be capable of providing enough power and current for both motors. For most applications where independent control and high precision are required, separate drivers for each motor are recommended.