Servo Motor Manufacturer

We design and produce various sizes of customized AC and DC servo motors, including micro and large servo motors. Whether it is high-precision positioning control or strong torque output, we can provide unparalleled performance and reliability for your equipment.

Apart from the standard servo motor, we can also provide you customized alternatives:

- Power Rating: 200W-3KW

- Voltage: 5v,12v,24v

- Torque Range: 1.5 Nm to 50 Nm

- Speed Range: 0-3000 RPM

- Encoder Type: Incremental, Absolute

- Water proof, silent,explosion proof

Home / Servo Motor

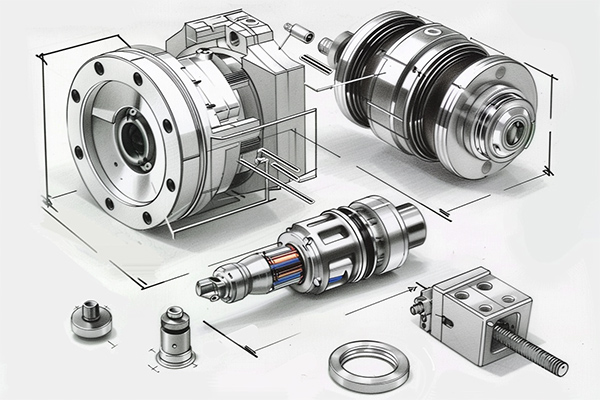

servo motor Component

- Stator: The stationary part generates motion through copper windings interacting with the rotor using laminated steel.

- Rotor: The spinning part, attached to the shaft, uses a steel core and magnets to create motion.

- Encoder: An incremental or absolute sensor attached to the motor shaft, provides feedback on position, speed, and direction.

- Housing: The aluminum or steel casing with IP65/IP67 protection ensures structural integrity and protects internal components.

- Feedback System: Sensors and encoders form an integrated system for monitoring motor performance, enabling precise control and adjustments.

- Control Electronics: Microcontrollers and power drivers manage motor operations, control power input, regulate speed, and ensure precise positioning.

By Current

DC Servo Motor

- Control: Easier with direct current

- Torque: High starting torque

- Speed Range: Wide speed range

- Feedback: Potentiometers, tachometers

- Efficiency: Generally less efficient

AC Servo Motor

- Control: More complex with inverters

- Torque: High torque at high speeds

- Speed Range: Stable across wide speeds

- Feedback: Encoders

- Efficiency: Industrial automation, aerospace

By Size

We provide micro and large servo motors to meet the needs of different industries. If you have any needs, please contact us!

Micro

Our micro servo motors for DC & AC.

- Size:20mm to 100mm

- Weight: 9g to 20g

- Torque: Lower torque output(0.1 to 1 kg·cm)

- Speed:reduced inertia leading to a quicker reaction time.

Large

Our large servo motors are generally AC.

- Size:1500mm-2000mm

- Weight: 100kg to 500kg.

- Torque: Lower torque output(10 to 100 kg·cm)

- Speed:Slower than micro servos

By Shaft Type

We offer dual shaft and hollow shaft options to meet any needs, please contact us!

Hollow Shaft

- The hollow shaft of the hollow shaft servo motor allows cables, pipes, or other elements to pass through, optimizing space and integrating additional components efficiently.

- Suitable for compact systems where components need routing through the motor.

Dual Shaft

- The dual shafts of the dual shaft servo motor allow driving two components simultaneously or controlling the motor's position from both ends.

- Suitable for systems requiring dual drive capabilities or enhanced feedback options.

By Motion Type

Our servo motor motion modes are divided into rotation and linear motion. If you have any needs, please contact us!

Rotary Motion

- Rotary servo motor provides rotational motion, allowing the motor shaft to turn clockwise or counterclockwise.

- Includes a motor, feedback device, and control electronics for precise angle control.

Linear Motion

- Linear servo motor generates linear motion by moving in a straight line as opposed to turning.

- Consists of a linear actuator, feedback device, and control electronics for accurate position control along a linear path.

By Voltage

Our conventional voltages are 5v, 12v, 24v, If you want to customize, please contact us!

5v

- 5V servo motor operates at a lower power output, making it suitable for lightweight and low-power applications.

- They integrate with micro controllers like Arduino easily.

12v

- 12V servo motor offers moderate power, balancing size and torque for medium-duty tasks effectively.

- Requires separate power but easy to integrate.

24v

- 24V servo motor offers high power, ideal for demanding applications needing substantial torque and performance.

- Requires dedicated power supply, robust control, adding complexity and cost.

By Phase

Our servo motors are available in 2-phase and 3-phase options. If you have any needs, please contact us!

2 Phase

- 2 phase servo motor has more torque ripple, resulting in less smooth motion and lower, less consistent torque.

- While offering simpler control and easier electronics, it is less precise but cheaper to manufacture and maintain.

3 Phase

- 3 phase servo motor provides smoother, more stable motion with higher and consistent torque due to overlapping phases.

- Three-phase power supply ensures smoother operation with continuous power and higher torque, offering better control over speed and position.

By Control System

Analog Control

Analog servo motor uses analog signals to control the motor, typically involving varying voltage levels to set positions or speeds

Digital Control

Digital servo motor utilizes digital signals for control, often featuring programmable parameters for precise operation. Commands are sent in discrete steps.

PWM Control

PWM servo motor can adjust torque, speed,or position by varying the width of their digital pulses.Commonly used in hobby and low-power applications.

PLC Control

PLC Servo Motor combines the precision control of a servo motor with the flexibility and programmability of a PLC.

Closed Loop Control

Closed loop servo motor uses sensor feedback to monitor and adjust performance in real-time, ensuring high accuracy and precision.

Position Control

Positional servo motor controls angle, position, and speed with high torque, fast response, and accurate feedback for diverse applications.

By Motor Type

PM (Permanent Magnet)

- PM servo motor utilizes permanent magnets to generate the magnetic field, which leads to high efficiency and reduced energy consumption.

- Provides high torque density and precise speed and position control, ideal for applications needing precise movements.

Synchronous

- Synchronous Servo Motor maintains consistent speed with supply frequency, essential for precise timing applications despite load changes.

- Outstanding performance and minimal energy loss make it ideal for high-performance CNC machines and robots.

Asynchronous

- Asynchronous Servo Motor uses induction for the magnetic field, leading to simpler, more rugged designs than synchronous motors.

- The motor speed changes with the load, ideal for applications prioritizing speed adaptability over precise control.

Applications

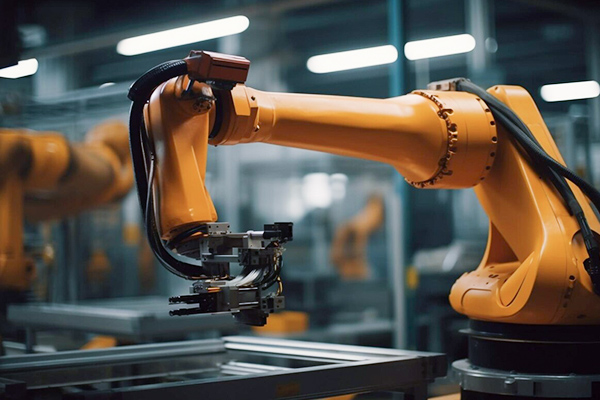

Industrial Automation

Conveyor systems employ industrial servo motors to regulate the speed and motion of conveyor belts during production and packing procedures.

Robotic

Robot servo motors are essential for precise positioning and movement in robotic arms used in manufacturing, assembly lines, and material handling.

CNC Machine

Spindle servo motors are employed for controlling the movement of tools in CNC (Computer Numerical Control) machines for precision machining and cutting.

Automotive

Servo motor car systems are utilized in drive-by-wire systems for electronic control of steering, throttle, and braking systems in modern vehicles.

Sewing Machine

Servo motors for sewing machines are implemented in advanced sewing machines to control the needle position, stitch type, and fabric feed for consistent & high-quality stitching.

Hydraulic Equipment

Hydraulic servo motor enable precise control, enhancing performance and accuracy in industrial machinery, robotics, and construction applications.