Coreless DC Motor Manufacturer

We specialize in manufacturing mini and small coreless electric motor, including Coreless BLDC motors and brushed coreless motor, diameters ranging from 4mm-50mm, designed for high speeds and maximum life, making them ideal for continuous duty and high-power applications

In accordance with the distinct requirements of your sector, we are also capable of offering you personalized services:

- Operating Voltage: e.g., 6V, 12V, 24V, etc.

- Mounting Options: e.g., flange mount, face mount, or custom mounts

- Sensor Options: For brushless motors, e.g., Hall effect sensors, encoder options

- Ingress Protection: Offer motors with different IP ratings for dust and water resistance (e.g., IP65, IP67).

Home / Coreless DC Motor

Structure

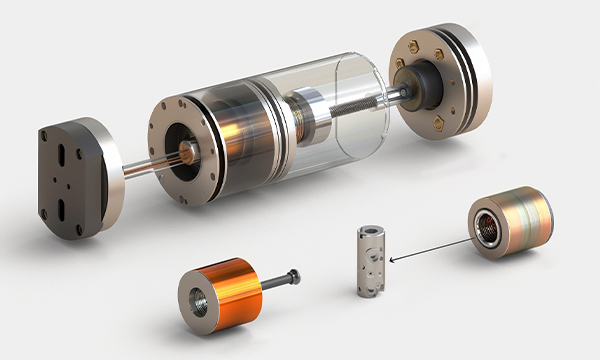

Coreless DC motors, also known as ironless DC motors, have a unique construction that distinguishes them from traditional DC motors.

- No Iron Core: Coreless bldc motors lack an iron core in the rotor, in contrast to conventional motors.The weight and inertia of the motor are greatly decreased by this design.

- Winding Configuration: The windings are typically made in a honeycomb or basket pattern, allowing for greater efficiency and smoother operation.

- Permanent Magnets: Coreless brushless DC motors use permanent magnets in the rotor, similar to other brushless motor designs, but with the absence of an iron core, they exhibit less cogging and smoother motion.

Direct Current (D.C.)

- Current Type: Operates on direct current (DC), where charge flows in one direction

- Features of Voltage: DC voltage is steady

- Commutation Method: Brushless and brushed DC motors are the two types of DC motors

- Control Complexity: The control mechanism of DC motors is simpler

- Torque and Speed Characteristics: DC motors have the advantages of high torque at low speeds and fast response time

- Applications: DC motors are the first choice for precision and portable applications

By Types

We provide a full range of custom coreless DC motors including coreless brushless DC motors and coreless brushed DC motors.

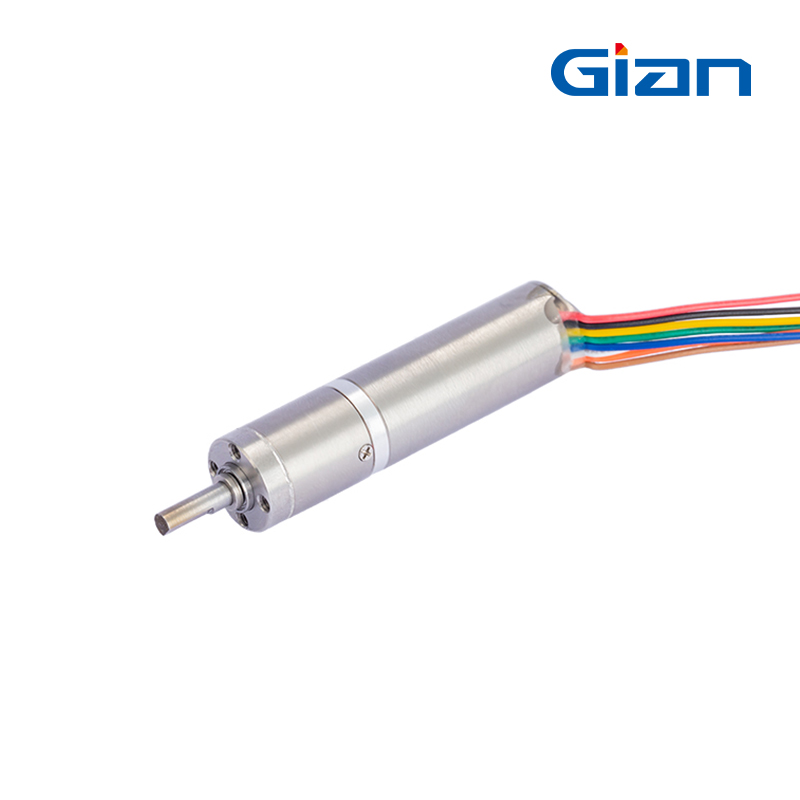

Coreless Brushless DC Motor

- Voltage Range: 6V to 48V

- Efficiency: Higher, usually 85-95%

- Construction: The rotor lacks an iron core and has honeycomb-patterned windings.

- Operation: Sensors & electronics control current switching, removing the need for brushes.

- Speed and Torque: Higher speed capabilities (up to 100,000 RPM) and torque density.

- Typical Uses: Aerospace, medical devices, high-precision robotics & industrial equipment.

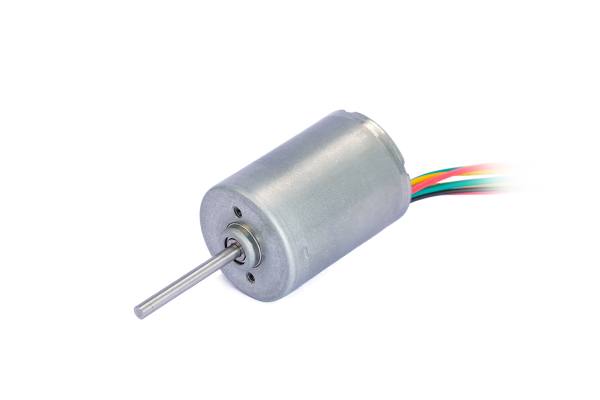

Coreless Brushed DC Motor

- Efficiency: Typically 70-80%.

- Voltage Range: 6V to 24V

- Construction: Coreless rotor design without an iron core, using patterned windings.

- Operation: Brushes contact the commutator to switch current, turning the rotor.

- Speed and Torque: Moderate speed (up to 30,000 RPM) and torque density.

- Typical Uses: Toys, small appliances, simple robotics, cost-sensitive applications.

By Diameter

The conventional diameters of our coreless dc motors are 7mm, 8mm, and 10 mm, and we can also customize the sizes according to your industry needs.

7mm Coreless DC Motor

- Torque: Lower compared to larger motors due to smaller size

- Speed: Typically high, suitable for applications needing quick responses

- Power Consumption: Lower, making it ideal for battery-powered devices

- Compactness: Excellent for space-constrained applications

8mm Coreless DC Motor

- Torque: Higher than 7mm motors, providing a balance between power and size

- Speed: Still high, but can handle slightly larger loads than 7mm motors

- Power Consumption: Moderate, balancing performance and efficiency

- Versatility: Offers a good compromise between compactness and performance

10mm Coreless DC Motor

- Torque: Highest among the three, suitable for applications needing more power

- Speed: Can be lower than smaller motors if optimized for torque

- Power Consumption: Higher, suited for applications where power availability is not a constraint

- Heat Dissipation: Better, due to larger surface area, but requires more power

From 0 to N - Full Motor Solutions

Applications

Medical Devices

- Surgical Tools: Precision control and low noise make coreless motors ideal for delicate surgical instruments.

- Diagnostic Equipment: Used in imaging devices like MRI and CT scanners for their smooth operation and high efficiency.

- Infusion Pumps: provide accurate and dependable control over the administration of fluids and pharmaceuticals.

Aerospace Instruments

- Avionics: Lightweight and responsive, suitable for control systems and instrumentation in aircraft.

- Satellite Systems: Used in satellite control mechanisms and payload systems for their reliability and precise movement.

- Unmanned Aerial Vehicles (UAVs): High efficiency and rapid response are beneficial for flight control systems.

Optical and Measurement Devices

- Cameras and Camcorders: Used in autofocus systems and image stabilization mechanisms for their precise control.

- Microscopes: Provides smooth and accurate movement for focusing mechanisms.

- Laser Scanners: Ensures precise and stable operation for high-resolution scanning applications.

Consumer Electronics

- Smartphones and tablets: Because of their small size and effectiveness, these devices are used in vibration alert systems.

- Wearable Devices: Lightweight and efficient, perfect for fitness trackers and smartwatches.

- Personal Care Devices: Employed in electric toothbrushes and shavers for smooth and quiet operation.

FAQ

What is a coreless DC motor, and how does it differ from traditional DC motors?

An iron core is not present in the rotor of a coreless DC motor; instead, wire windings are used. Compared to conventional DC motors, this design's reduction in weight and inertia leads to increased efficiency and quicker reaction times.

How does a coreless brushless DC motor operate without brushes, and what are its advantages?

A coreless brushless DC motor uses electronic commutation with sensors to detect the rotor's position and switch current through the windings. It offers higher efficiency, longer lifespan, lower maintenance, and reduced electrical noise.

What are the key differences between a brushed coreless motor and a coreless brushless DC motor?

A brushed coreless motor uses brushes and a commutator, while a brushless coreless DC motor uses electronic commutation. Brushless motors are more reliable and efficient than brushed motors, which are more expensive yet need more maintenance.

What are the usual uses for a 12V coreless motor, and what makes 12V a standard voltage?

12V coreless motors are used in portable devices, robotics, automotive applications, and small appliances due to their availability in battery systems and balanced power efficiency.

What are the benefits of using a coreless micro motor in precision applications?

Coreless micro motors offer high efficiency, low weight, and minimal cogging for smooth, precise motion, crucial for precision applications like medical devices, micro-robotics, and fine instrumentation.

How does the absence of an iron core in a coreless DC motor contribute to its performance?

A coreless DC motor may accelerate and decelerate more quickly because it has less weight and inertia due to the absence of an iron core.Additionally, it increases effectiveness and decreases cogging, leading to smoother and more accurate motion control.