Spur Gear Motor

Experience the adaptability and effectiveness of our 50mm to 150mm diameter micro and small spur gear motors. They operate quietly while delivering strong torque and reliable performance. Their sturdy construction guarantees longevity and dependability, which makes them perfect for both light- and heavy-duty jobs.

In addition, we also offer custom motor services to precisely meet your specific requirements:

- Encoder

- Voltage

- Size

- Custom shaft

Home / Spur Gear Motor

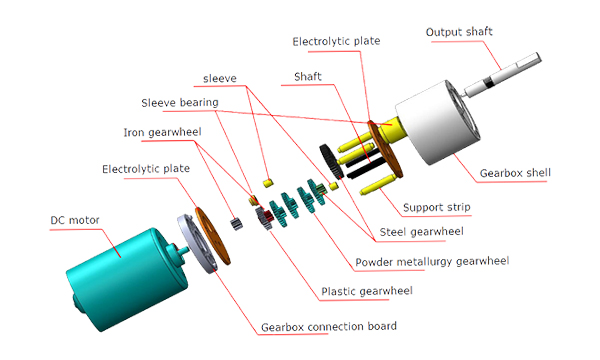

Structure

- Input Shaft: Connects to the motor output shaft and transmits the motor's power into the gearbox.

- Spur Gears: Transmit motion and torque through meshing with each other, changing the speed and torque.

- Intermediate Shafts: Connect multiple gears and transmit power and motion.

- Output Shaft: Delivers the adjusted speed and torque to the final load.

- Bearings: Support the shafts and gears, reduce friction, and ensure smooth rotation.

- Housing: Protects internal components, prevents dust and contaminants from entering, and contains lubrication oil.

- Seals: Prevent lubrication oil leakage and keep the gearbox interior clean.

- Lubrication System: Reduces friction of gears and bearings, extending their lifespan.

By Types

Brushless DC Spur Gear Motors

- 85-90% efficiency & better performance.

- Require less maintenance & are more durable.

- More complex and expensive.

- Uses an electronic controller to switch current, eliminating brushes and a commutator.

Brushed DC Spur Gear Motor

- Lower initial cost and simpler design.

- Have a limited lifespan & need frequent maintenance.

- 70-75% efficiency and precise.

- Contains brushes and a commutator to mechanically switch current in the windings.

By Current

DC

- Power Source: Direct current (DC) motors operate using DC electrical power typically from batteries or rectified AC power.

- Speed Control: With DC motors, precise speed control is possible by voltage variation or pulse width modulation (PWM).

- Torque Characteristics: Generally, DC motors provide higher starting torque compared to AC motors of similar size.

- Maintenance: Because of their less complicated design and fewer parts, they are frequently easier to maintain.

AC

- Power Source: Alternating current (AC) motors operate directly from AC mains power.

- Speed Control: Unless they are fitted with variable frequency drives (VFDs) for speed adjustment, AC motors normally run at set speeds.

- Starting Torque: Compared to DC motors of the same size, AC motors often have a lower starting torque.

- Maintenance: Because of its more intricate design and extra parts like capacitors and starting mechanisms, they could need more maintenance.

From 0 to N - Full Motor Solutions

Featured products

TR093-P01

- Size: 112.8*45.81*23.5mm

- Rated Voltage:12V

- Rated Speed: 100±10% RPM

- Rated Current: ≤1.2A

.jpg)

YF003-P01

- Size: 55.4*45.15mm

- Rated Voltage: 4-8.4V

- No-load Speed: 0.133 sec/ 60°(75RPM)

- No-load Current: 50mA

TR095-P01

- Size: 47.5*36mm

- Rated Voltage: 12V

- Rated Current: 0.35A Max

- Rated Torque: 0.15N.M

TR003-P01

- Size: 68*75.6mm

- Rated Voltage: DC 12V

- Operating Voltage: 9V-15.5V

- Maximum Instantaneous Current: 3.2A

Applications

Automotive Industry

- Power windows

- Windshield wipers

- Seat adjusters

Medical Devices

- Diagnostic equipment

- Infusion pumps

- Prosthetics

Agriculture

- Automated feeding systems

- Greenhouse ventilation systems

- Seed dispensers

Office Equipment

- Shredders

- Fax machines

- Vending machines

Home Automation

- Automatic curtains and blinds

- Garage door openers

- Smart locks

Industrial Equipment

- Conveyor systems

- Material handling equipment

- Automated assembly lines

FAQ

What are spur gear motors?

Spur gear motors are a type of gear motor that utilizes spur gears to transfer motion and power between parallel shafts. They are renowned for being easy to use, dependable, and reasonably priced.

How do spur gears function within the motor?

Spur gears function by meshing their teeth together to transfer rotational motion and power between parallel shafts. The gear ratio determines the output speed and torque of the motor.

What distinguishes a flat spur gear motor from a round spur gear motor?

A round spur gear motor is cylindrical and compact, while a flat spur gear motor has a low-profile, pancake-like design, ideal for tight vertical spaces.

What is the types of spur gear motor?

Parallel Shaft Spur Gear Motors, Right Angle Spur Gear Motors, Inline Spur Gear Motors, Offset Spur Gear Motors, Planetary Spur Gear Motors, Helical Spur Gear Motors

What are common issues with spur gear motors and how can they be resolved?

Common issues are excessive noise (fix: align and lubricate), overheating (fix: check load and lubricate), and gear wear (fix: inspect and replace gears).

What are the key advantages of using spur gear motors?

Advantages include simple design, high efficiency, cost-effectiveness, and reliable performance.