Harmonic Drive Motor

We offer high-precision harmonic drive actuators with zero backlash, compact size, high torque-to-weight ratio, smooth operation, and reliable performance for precise and efficient motion control.

We can offer specialized services for our goods based on the demands of your sector, such as:

- Diameter: 20 mm to 200 mm

- Torque Output:1 Nm to 5000 Nm

- Reduction Ratio: 30:1 to 320:1

- Positioning Accuracy: ±10 arc-seconds to ±1 arc-minute

- Backlash: Zero or near-zero

- Repeatability: ±1 to ±5 arc-seconds

Home / Harmonic Drive Motor

Structure

Motor

- Type: Typically a brushless DC motor or stepper motor.

- Rotor: Connected directly to the wave generator.

- Stator:Contains windings, creating the electromagnetic field.

Integration Mechanism

- Direct Coupling: The motor rotor is directly coupled to the wave generator.

- Mounting Flange: Enables easy assembly mounting to structure.

- Feedback Sensors: Encoders or resolvers for precise position and speed feedback.

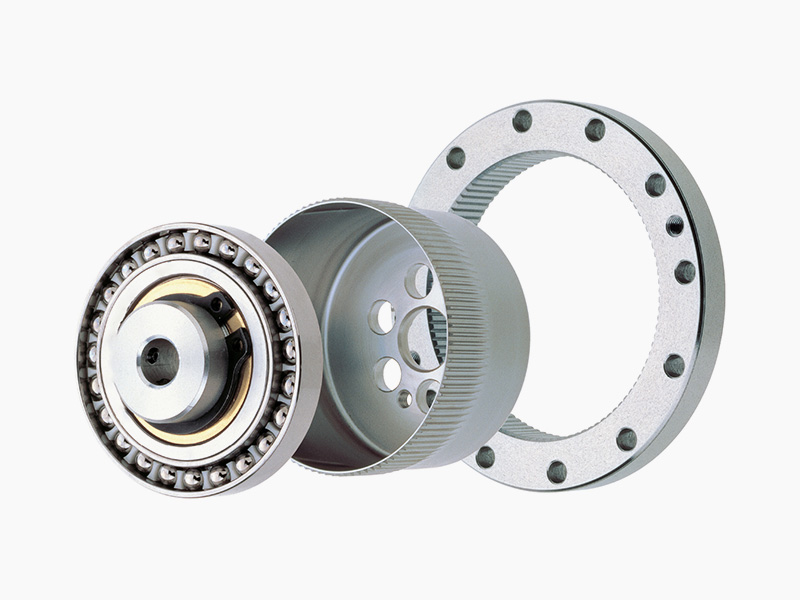

Harmonic Gearbox

Wave Generator

- Elliptical Cam: The core of the wave generator.

- Flexible Bearing: Encases cam, transfers motion to flexspline.

Flexspline

- Flexible Gear: Slim, spherical, and conforms to the form of the wave producer.

- External Teeth: Mesh with the circular spline’s internal teeth.

Circular Spline

- Rigid Gear: With internal teeth slightly more than the flexspline.

- Stationary Component: Typically fixed to the motor housing.

Featured Products

Parameter | Value |

Gear Ratio | 50:1, 80:1, 100:1 Ratio |

Rated Torque | 10 – 1000Nm |

Max Torque | 30 – 3000Nm |

Rated Speed | 15 – 150RPM |

Max Speed | 50 – 500RPM |

Backlash | < 1 arc-min |

Efficiency | 70% – 85% |

Reduction Stages | Single-stage |

Operating Temperature | -20 to +80°C |

Input Voltage | 24V, 48V, 220V |

Motor Type | Brushless DC, Stepper |

Weight | 0.5 – 15kg |

Noise Level | < 60 dB |

Lifetime | 10,000 – 20,000 hours |

Lubrication Type | Grease |

From 0 to N - Full Motor Solutions

By Motion Type

Rotational Motion

- Harmonic drive motor is predominantly used for precise rotational motion. The unique gear design allows for accurate and smooth rotation.

- Essential in many applications like robotics, aerospace, and industrial automation.

Linear Motion

- Using lead screws or linear actuators, harmonic gear motors' rotational motion converts to precise linear motion for accurate positioning and actuation.

- Some harmonic drives are designed for linear motion, using strain wave gearing principles for high precision and low backlash.

Applications

Precision Instruments

- Optical Instruments: Used in high-precision alignment systems for telescopes and microscopes.

- Micro-Manipulation: Employed in devices that require fine and precise movement control, such as in micro-assembly and fiber optics handling.

Robotics

- Humanoid Robots: Used in joints for smooth and precise movements, replicating human-like dexterity.

- Mobile Robots: Essential in the drive systems of mobile robots for precise navigation and operation in dynamic environments.

Medical Devices

- Surgical Robots: Offers precise control in minimally invasive surgery, allowing for delicate and accurate manipulation of surgical instruments.

- Diagnostic Equipment: Utilized in MRI and CT machines for accurate positioning and scanning.

Aerospace

- Flight Simulators: Used in control systems for realistic and precise simulation of aircraft movement.

- Aerospace Actuators: Critical in control surface actuation and other mechanisms requiring high reliability and precision.

Semiconductor Manufacturing

- Wafer Handling Systems: Enables precise, clean handling of semiconductor wafers in manufacturing processes.

- Lithography Equipment: Provides accurate positioning in photolithography systems for the precise patterning of semiconductor materials.

Defense

- Military Robotics: Used in unmanned ground and aerial vehicles for precise movement and operation in complex environments.

- Surveillance Systems: Enables precise positioning in advanced surveillance and targeting systems.

FAQ

How is backlash minimized in harmonic gear motors?

The flex spline's continuous engagement with the circular spline reduces backlash by preventing gaps and guaranteeing steady contact.

What upkeep is necessary for motors with harmonic gears?

To guarantee optimum performance and longevity, maintenance usually entails routine inspection and lubrication. Due to their robust design, they generally require minimal maintenance.

Which elements come into play while choosing a harmonic gear motor?

When choosing a harmonic gear motor for a given application, take into account variables including the required torque, accuracy, speed, size restrictions, and environmental factors.