Transmission System Solutions

For Industrial Automation

Home / Industrial Automation

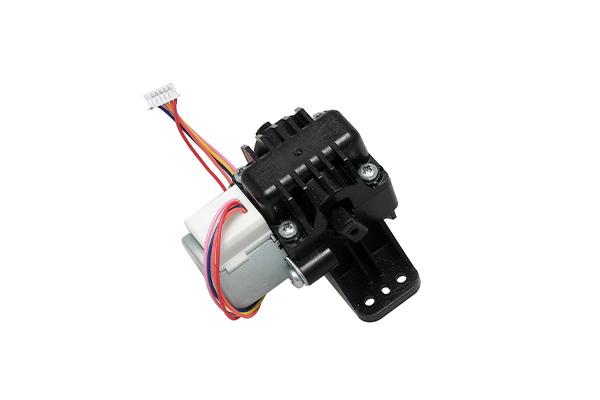

China’s industrial industry has a huge possibility to be upgraded and transformed by Industry 4.0. Amid the global technological innovation driven by smart manufacturing, micro-drive systems are becoming crucial as one of the four key industrial foundations for industrial upgrading.

Jingyan, with its deep understanding of drive applications and customer needs, leverages years of technical expertise and precision craftsmanship. In order to create goods that meet consumer and market needs, we put a strong emphasis on quality.

Committed to continuous improvement, we continually push the boundaries of drive technology, striving for high-quality and high-performance micro-drive production to support the dynamic growth of industrialization.

Jingyan, with its deep understanding of drive applications and customer needs, leverages years of technical expertise and precision craftsmanship. In order to create goods that meet consumer and market needs, we put a strong emphasis on quality.

Committed to continuous improvement, we continually push the boundaries of drive technology, striving for high-quality and high-performance micro-drive production to support the dynamic growth of industrialization.

Reduced Maintenance

Their robust design and reliability lead to lower maintenance needs and fewer downtimes.

Enhanced Control

They enable fine-tuned control of various automated systems, improving overall process accuracy and efficiency.

Fast Response Time

Micro motors have quick response times, allowing for rapid adjustments and increased production speeds.

Low Heat Generation

Because of their effective design, systems last longer and require fewer cooling systems. This also reduces heat generation.

Intelligent Application

Construction Machinery

- Precision Control: Large machinery such as excavators and cranes are precisely controlled by use of micro motors.

- Sensor Adjustment: They adjust sensors to monitor equipment performance & conditions.

Agricultural Equipment

- Automatic Adjustments: Adjust harvester, planter, and tractor settings for optimal performance.

- Spraying Systems: They regulate the flow and direction of pesticide and fertilizer sprayers.

Mining Equipment

- Drill Positioning: Micro motors precisely position drilling equipment for efficient, safe operations.

- Conveyor Systems: They operate small components in large ore conveyor systems.

Material Handling

- Automated Guided Vehicles (AGVs): Micro motors drive AGVs in warehouses and ports for precise handling.

- Cranes and Lifts: They precisely control lifting & moving heavy materials in small components.

Semiconductor Manufacturing

- Wafer Handling: Move wafers between processing steps.

- Equipment Adjustment: Fine-tune the position of components within manufacturing equipment.

Textile Processing Machinery

- Looms and Weaving Machines: Accurate operation and pattern creation.

- Spinning Machines: Manage the speed and tension of fibers.

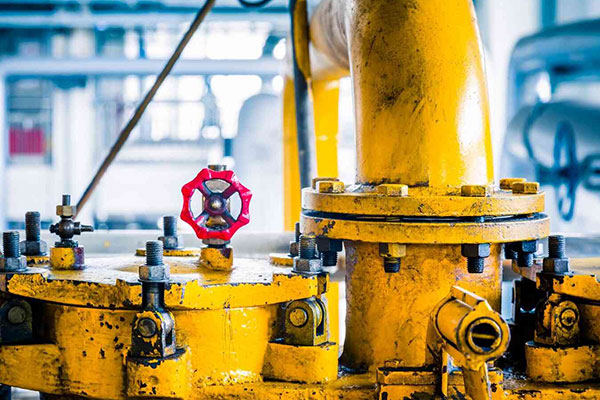

Heavy Equipment Control Systems

- Valve and Pump Adjustment: Precision control in hydraulic systems.

- Sensor Feedback Mechanisms: Enhance automated control systems for large machinery.

Snow Removal Equipment

- Blade Adjustment: Control angle and position of snowplow blades.

- Spreader Systems: Regulate the distribution of salt and sand.