Brushless DC motor Manufacturer

We are committed to designing and producing various types of micro and small BLDC motors, and offering excellent speed control, low maintenance, and energy savings. We have complete size series from 20mm-125mm and power range of 1W to 1500W.

Based on your industry needs, we provide custom options:

- Diameter: 5mm-50mm

- Length: 20mm-140mm

- Rated voltage: 5V-24V

- No-load speed:10000 rpm-80000 rpm

- Noise: 0-60 dB

Home / Brushless DC Motor

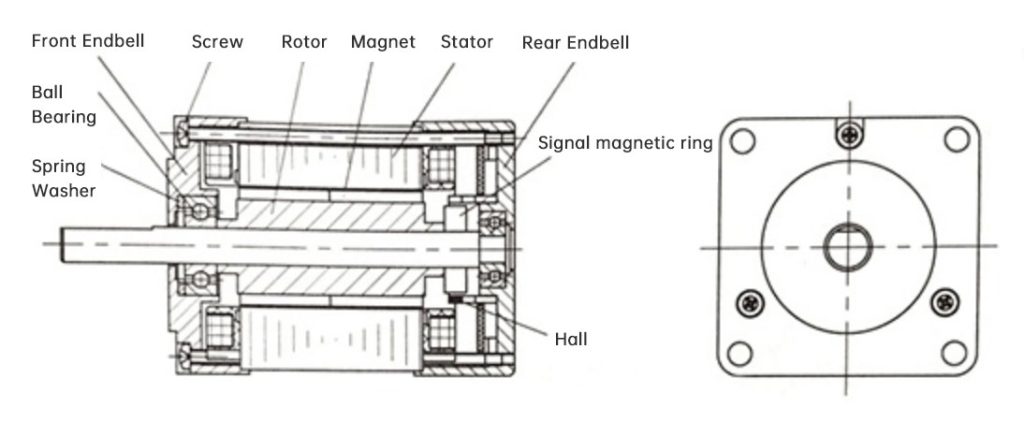

BLDC MOTOR Structure

They use electronic commutation instead of brushes, reducing wear.This leads to better speed-torque performance, precise control, and higher reliability.

- Rotor: Contains permanent magnets that create a magnetic field.

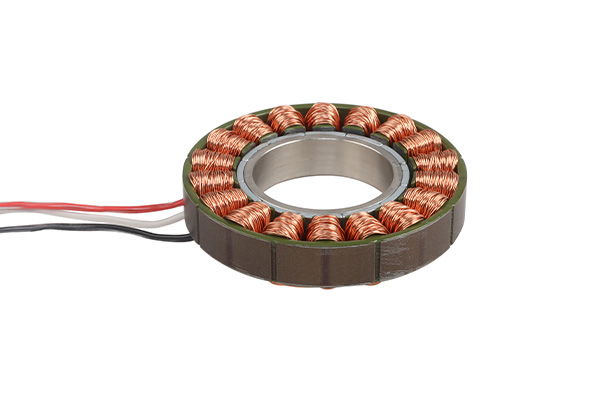

- Stator: Laminated iron core with copper windings generates the electromagnetic field.

- Housing: Encloses and safeguards the motor's internal components.

- Bearings: Support the rotor, enabling smooth, low-friction rotation.

- Electronic Speed Controller (ESC): Regulates motor winding power using feedback.

- Hall Sensors or Encoder: Provide rotor position feedback for precise control.

- Shaft: Transfers mechanical power from the motor to the load.

By Types

We provide a full range of custom brushless DC motors including outrunner, inrunner and Brushed DC Motor.

Outrunner Brushless DC Motor

- Construction: Stator inside, rotor outside

- Torque: High torque due to larger diameter

- Speed: Moderate, RPM range(10800 rpm-21000rpm)

- Efficiency: High due to reduced iron losses

- Applications:Drones, e-bikes

Inrunner Brushless DC Motor

- Construction: Rotor inside, stator outside

- Torque: Lower torque, higher RPM

- Speed: Higher RPM range(9800rpm)

- Efficiency: High, but less than outrunner

- Applications:RC cars, electric vehicles

production process

Material Procurement

Raw Materials: Source copper wire, silicon steel, magnets, components.

Quality Control: Check materials meet required specifications for quality.

Component Manufacturing

Stator Manufacturing:

Lamination Stamping: Stamp silicon steel sheets into stator laminations.

Lamination Stacking: Stack and bind the laminations to form stator core.

Winding: Wind copper wire for windings.

Rotor Manufacturing:

Lamination Stamping: Stamp laminations for the rotor core.

Magnet Insertion: Insert magnets into rotor core if needed.

Shaft Assembly: Attach the rotor core to the motor shaft.

Assembly

Housing and Bearings: Assemble the motor housing and insert the bearings.

Stator Assembly: Insert the stator into the housing and secure it.

Rotor Assembly: Insert rotor into stator, ensuring alignment and clearance.

Electronic Control Assembly

PCB Manufacturing: Produce PCBs for the control electronics.

Component Placement: Place electronic components on the PCBs.

Soldering: Solder the components onto the PCBs.

Firmware Programming: Program the firmware into the microcontroller on the PCB.

Final Assembly

Control Circuit Integration: Integrate the control electronics with the motor assembly.

Wiring and Connections: Connect the windings and sensors to the control circuit.

Enclosure Sealing: Seal the motor housing to protect the internal components.

From 0 to N - Full Motor Solutions

By Design

The design of slotless, frameless and flat share the characteristic of compact design optimization for various space-constrained applications.

Slotless

- The stator has windings placed in a smooth cylindrical core or a configuration that avoids the use of slots.

- Slotless brushless dc motor in a high-precision CNC spindle ensures smooth, high-speed rotation with minimal vibration.

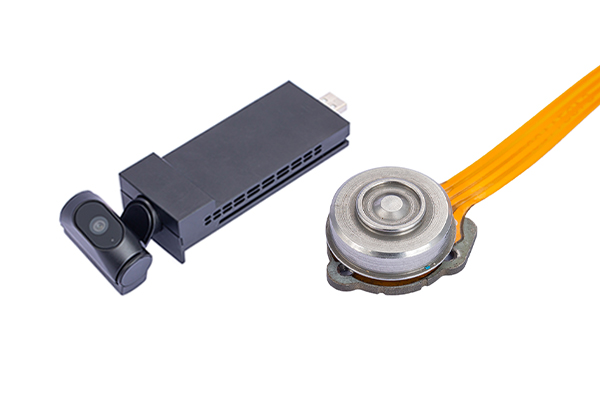

Frameless

- Frameless brushless DC motors lack an external frame, consisting of rotor and stator for direct integration.

- Integrated into robotic surgical arms, offering precise movement and control without adding significant weight or bulkiness.

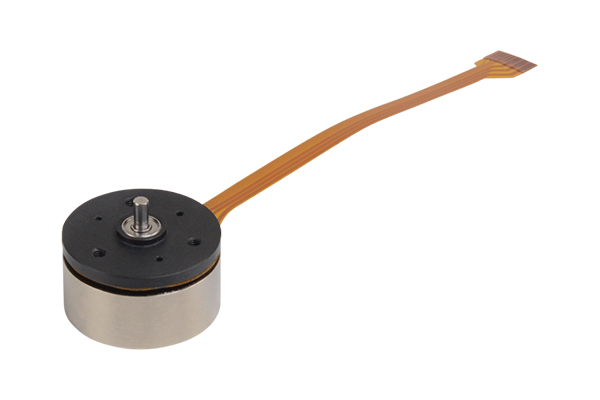

Flat

- Flat Brushless DC Motor, with a pancake design and large diameter, delivers high torque at lower speeds.

- Used in a compact AGV, providing the necessary torque to move heavy loads while fitting within a restricted vertical space.

By Control Method

The control of PWM, sensorless, and sensored all provide efficient and precise speed control capabilities.

PWM

- Brushless DC motor PWM controls speed and torque using Pulse Width Modulation (PWM), adjusting the PWM signal duty cycle for regulation.

- Provides fine control over motor speed and torque, efficient power consumption, and is simpler and more cost-effective to implement.

Sensorless

- Sensorless brushless DC motor uses back EMF (Electromotive Force) detection to estimate the rotor position without physical sensors.

- The controller uses motor-generated voltage for commutation timing, ideal for sensorless, space-limited, cost-sensitive applications.

Sensored

- Sensored brushless motor utilizes sensors (Hall effect sensors or encoders) to detect the rotor position and provide feedback to the controller.

- It ensures accurate commutation timing, switching current in motor windings to maintain rotation, common in precise robotics and CNC control.

By Phase

Our bldc motors can be equipped with three phase, two phase, and single-phase to meet your different needs. If you want to customize, please contact us!

3-Phase Brushless DC Motor

- Features three 120°apart stator windings.

- Uses a three-phase inverter for commutation.

- Provides smooth torque output due to the overlap of phases.

- Utilizes Hall sensors or encoders for precise control.

2-Phase Brushless DC Motor

- Has two stator windings spaced 90°apart.

- Requires a two-phase inverter for commutation.

- Generates pulsating torque unlike 3 phase motors.

- Often uses simple control methods.

Single-Phase Brushless DC Motor

- Has a single stator winding.

- Uses a single-phase inverter for commutation.

- Produces a highly pulsating torque output.

- Simple construction and control mechanisms.

By Shaft Design

Both the design of hollow shaft and dual shaft offer versatile shaft configurations for diverse applications. If you want to customize, please contact us!

Hollow Shaft

- Hollow Shaft Brushless DC Motor features a hollow shaft through its center, allowing the passage of cables, pipes, or other components through the motor.

- Enables integration of components within the motor's footprint, ideal for applications needing through-hole design.

Dual Shaft

- Dual Shaft Brushless DC Motor, equipped with two output shafts on either side, allows for power transmission to two separate devices simultaneously.

- Can drive two mechanisms at once, reducing the need for additional motors, balancing load across shafts, useful where space requires opposite power.

By Voltage

In addition to regular voltages, we can also customize other voltages according to your industry requirements. Please contact us!

5v

- 5V brushless DC motor is ideal for low-power applications, particularly in compact and low-voltage settings such as cooling fans, miniature robots, and small toys.

- These motors consume minimal power and generate little heat, making them suitable for portable and wearable technologies.

12v

- 12V brushless DC motor balances power and size, is used in electric power steering, fuel pumps, ventilation fans, vacuum cleaners, and power tools.

- The 12V rating offers a balance of performance and compatibility with standard power supplies, ensuring efficiency and reliability for continuous and intermittent use.

24v

- 24V brushless DC motor designed for high power applications, provides more torque and speed with greater efficiency and sustained performance.

- Used in industrial automation, robotics, and large electric vehicles, these robust motors handle heavy loads, ideal for demanding environments requiring precision and durability.

Applications

Electric Vehicles (EVs): Brushless DC motors are ideal for e-bikes, electric cars, and scooters due to their high efficiency, durability, and low maintenance needs.

Industrial Automation: Industrial brushless DC motors are utilized in robotic arms, CNC machines, and conveyor systems, offering precise control and high torque.

Consumer Electronics: These motors power devices like computer cooling fans, hard drives, and DVD players, offering reliable and quiet operation.

Drones and UAVs: The lightweight and efficient design of bldc electric motor makes them ideal for powering the propellers of drones and unmanned aerial vehicles.

Household Appliances: Applications include vacuum cleaners, washing machines, and air conditioners, where efficiency and longevity are critical.

Medical Devices: brushless DC electric motor are integral to medical equipment like pumps, ventilators, and surgical tools, valued for their precision and reliability.