Servo motors and stepper motors are two of the most commonly used motor types in industries like robotics, automation, and CNC machinery. Though they both serve as actuators, the choice between them depends on various performance factors like torque, speed, system control, and more.

Servo Motors

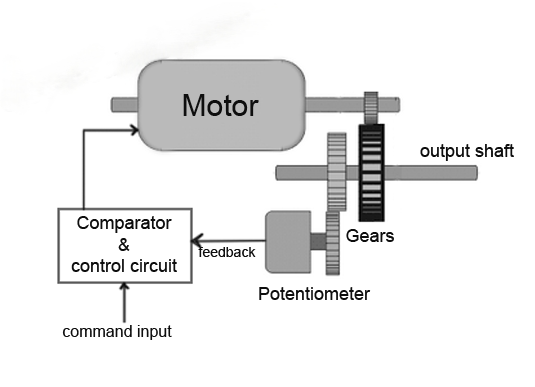

The exact control of acceleration, speed, and angular or linear placement is a feature of servo motors. They are closed-loop systems that require feedback to monitor performance and adjust the motor’s position accordingly. Because of their great precision and reactivity, servo motors are frequently utilized in industrial automation, robotics, and CNC machines.

Pros:

- High precision and accuracy due to closed-loop control.

- Capable of high-speed operation with consistent torque output.

- Can operate under heavy loads without losing steps.

- Power-efficient as it only draws current as needed.

Cons:

- More expensive due to added components like encoders and controllers.

- More complex setup requiring tuning and calibration.

- Requires a higher level of maintenance.

Stepper Motors

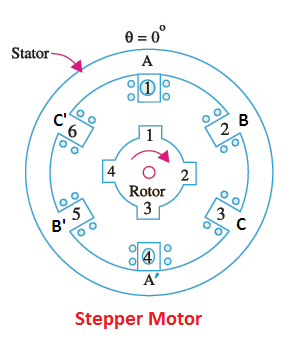

In contrast, stepper motors are made to move in distinct steps. They are open-loop systems, meaning that they operate without requiring feedback to control their position. In applications like 3D printers, textile machinery, and other automation processes where repeatability and exact positioning are essential, stepper motors are frequently utilized.

Pros:

- Simple and low-cost solution for applications requiring precise control.

- High holding torque without requiring constant current.

- No feedback needed, making it a straightforward control system.

- Ideal for low-speed, high-torque applications.

Cons:

- Limited speed range with a rapid drop in torque at higher speeds.

- Can lose steps under load without any way to correct errors.

- Less power-efficient as it draws current continuously even when holding.

Working Principles Comparison

Servo Motor Working Principle

A servo motor uses a feedback loop (such as an encoder) to constantly monitor its actual position and adjust it based on the desired position sent by the controller. The feedback loop ensures high precision. The motor’s speed and torque can be adjusted continuously, allowing for smooth operation.

- Closed-loop feedback system: Continuously monitors and adjusts.

- Control signal: Varies the duty cycle of a pulse-width modulation (PWM) signal.

- Motor type: Usually either DC brushless brushed, or AC motors.

- Encoder: Used for position feedback.

Stepper Motor Working Principle

Stepper motors work by splitting a complete rotation into many stages, usually between 200 and 400 steps per revolution. Every step has a corresponding rotational angle. Unlike servo motors, stepper motors don’t need position feedback as they inherently divide movement into distinct steps.

- Open-loop control system: No feedback mechanism, but the precise step control ensures accuracy.

- Step angle: The rotation per pulse, typically 1.8° for 200-step motors.

- Control signal: Pulses sent to the motor drive determine the number of steps.

Current and Power Consumption

The current requirements of servo motors and stepper motors differ significantly due to their working principles and applications.

| Motor Type | Operating Current | Power Consumption | Current Regulation |

| Servo Motor | Variable, depends on load | Generally lower at idle, higher under load | Closed-loop current regulation based on feedback |

| Stepper Motor | Constant, regardless of load | Higher overall power consumption due to constant current draw | Open-loop, no feedback |

- Servo Motors: The current draw of a servo motor is variable and directly related to the load and torque requirements. When the motor is not moving or holding a position, it consumes less power. However, under heavy load, the current increases as the feedback system adjusts the power to maintain performance.

- Stepper Motors: Stepper motors draw a constant current regardless of load. This characteristic results in higher power consumption, even when the motor is not moving or under low load conditions.

Torque and Speed Comparison

Torque and speed are two critical factors in determining the suitability of a motor for a particular application.

| Motor Type | Max Torque | Torque at High Speed | Torque Ripple |

| Servo Motor | High | High | Low |

| Stepper Motor | Moderate | Low at higher speeds | High |

- Servo Motors: Servo motors are known for their ability to deliver high torque, even at high speeds, making them ideal for dynamic applications where rapid changes in velocity and torque are required. They exhibit low torque ripple due to their continuous feedback loop, ensuring smooth motion.

- Stepper Motors: At low speeds, stepper motors produce a lot of torque; but, as speed increases, torque is much reduced. Their employment in applications requiring both high speed and torque is restricted by this feature. Stepper motors also experience torque ripple, leading to less smooth motion compared to servo motors.

Torque-Speed Graph Comparison

To visualize the difference, let’s look at the typical torque-speed curves for both motor types.

- Servo Motor: Over a large range of speeds, torque is comparatively constant.

- Stepper Motor: Torque decreases drastically as speed increases.

System Control Comparison

System control is one of the primary areas where servo and stepper motors differ. Servo motors typically use closed-loop control systems, while stepper motors rely on open-loop systems.

| Motor Type | Control System | Accuracy | Feedback |

| Servo Motor | Closed-loop | Very high | Encoder (position feedback) |

| Stepper Motor | Open-loop | Moderate | No feedback |

- Servo Motors: Servo systems use closed-loop feedback, typically from encoders, to monitor and adjust position and speed in real time. This allows for high precision, especially in dynamic and complex applications where real-time adjustments are critical. If the motor experiences an overload or a loss of position, the feedback system detects it and makes corrections.

- Stepper Motors: Stepper motors operate on open-loop control systems, where the controller sends pulses to the motor to achieve the desired position. There is no feedback, meaning the system has no way of knowing if the motor has reached the correct position or not. This can lead to missed steps or inaccurate positioning under certain conditions, such as when there’s an unexpected load.

Pole Count Comparison

The number of magnetic poles in the stator of a motor that works in tandem with the rotor to generate motion is known as the pole count. This number significantly affects the performance of both servo and stepper motors.

| Motor Type | Typical Pole Count | Effect on Performance |

| Servo Motor | Low (6-12 poles) | Higher speed, lower resolution |

| Stepper Motor | High (50-200 poles) | Lower speed, higher resolution |

- Servo Motors: Servo motors typically have a lower pole count (6 to 12 poles), which allows them to operate at much higher speeds. However, due to the lower pole count, they may require more complex control mechanisms to achieve the same resolution as stepper motors.

- Stepper Motors: Stepper motors have a significantly higher pole count, often ranging from 50 to 200 poles. This high pole count enables finer control over motor position (high resolution), but it limits the maximum speed the motor can achieve.

Cost Comparison

| Motor Type | Initial Cost | Operational Cost (Energy, Maintenance) | Lifetime Cost |

| Servo Motor | $300 – $1100+ | Low (high power efficiency, moderate maintenance) | $500 – $2,000+ |

| Stepper Motor | $50 – $300 | Moderate to high (constant energy use, low maintenance) | $100 – $500 |

- Servo Motors: Higher upfront and maintenance costs, but more energy-efficient over time, with better performance in high-speed and high-torque applications. In challenging circumstances, they offer a better long-term return on investment (ROI).

- Stepper Motors: Lower initial and operational costs make them ideal for budget-sensitive applications with low to moderate performance requirements. They are excellent for lower-speed applications that don’t require high precision or dynamic load handling.

Application Attributes

The particular application and the demands for torque, speed, and accuracy play a major role in the decision between a servo motor and a stepper motor.

|

Application Attributes for Stepper vs.Servo |

|||||||||||||||||

| Application Requirements | Stepper | Servo | Application Requirements | stepper | Seryo | Application Requirements | Stepper | Servo | Application Requirements | stepper | Seryo | Application Requirements | Stepper | Servo | Application Requirements | stepper | Seryo |

| Highest Torque Density | √ | Detent Torgue | √ | Highest Torque Density | √ | Detent Torgue | √ | Highest Torque Density | √ | Detent Torgue | √ | ||||||

| Largest Torque and Speed Range | √ | Inertia Loads up to 30:1(J_load :Jm) | √ | Possible | Largest Torque and Speed Range | √ | Inertia Loads up to 30:1(J_load :Jm) | √ | Possible | Largest Torque and Speed Range | √ | Inertia Loads up to 30:1(J_load :Jm) | √ | Possible | |||

| Open-Loop(typical) | √ | Inertia Loadsup to 200:1(J_load :Jm) | Possible | DD+(R/L)* | Open-Loop(typical) | √ | Inertia Loadsup to 200:1(J_load :Jm) | Possible | DD+(R/L)* | Open-Loop(typical) | √ | Inertia Loadsup to 200:1(J_load :Jm) | Possible | DD+(R/L)* | |||

Conclusion

Stepper motors and servo motors each have advantages and disadvantages. The application requirements, such as torque, speed, and control system complexity, determine which motor should be used.

Servo motors are preferred in high-precision, high-speed, and dynamic environments due to their closed-loop control and high performance across varying speeds. Stepper motors, on the other hand, are suitable for low-cost, low-to-moderate-speed applications where open-loop control suffices.