Brushless DC (BLDC) motors have become an essential part of modern automation and electric propulsion systems due to their efficiency, reliability, and ability to operate without brushes, resulting in longer lifespans. One of the most common challenges that arise in BLDC motor applications is the need to change the motor’s direction of rotation. Changing the direction of rotation in BLDC motors can be essential for various applications, from robotics to industrial machinery, where bidirectional movement is required.

We’ll explore several methods to reverse the direction of rotation of a BLDC motor, the theory behind these approaches, and practical steps to implement them. Additionally, we will cover the significance of Hall sensors, control signals, and how reversing the rotation impacts the motor’s performance.

Basic Principle of BLDC Motor Operation

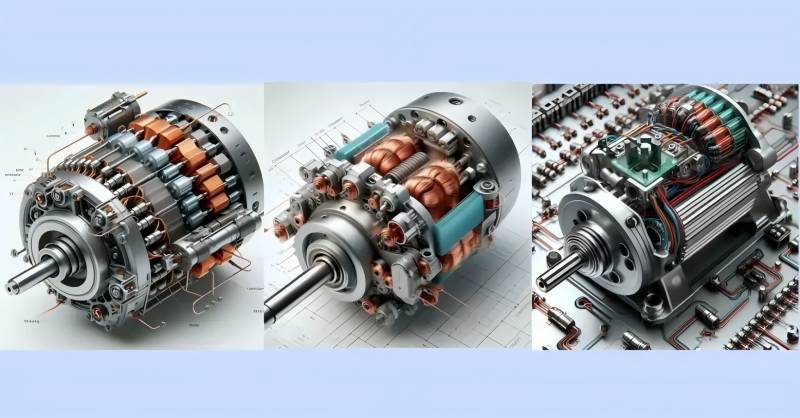

To understand how to change the direction of rotation of a BLDC motor, it’s crucial to first understand how these motors function. The rotor of a brushless DC motor is typically made up of permanent magnets, and the stator is made up of wire coils that produce magnetic fields. Based on the electromagnetism principle, the motor rotates by means of interaction between the rotor and a revolving magnetic field produced by the stator.

Key Elements

- Hall Sensors: These sensors feed the rotor position data to the controller, which adjusts the commutation of the stator windings accordingly to maintain rotation.

- Commutation Sequence: A BLDC motor’s rotation depends on the precise switching of current between stator windings. The controller energizes specific stator coils at the right time to push or pull the rotor in a particular direction.

Factors Affecting Motor Rotation Direction

The direction of rotation of a BLDC motor depends primarily on the order in which current is applied to the stator coils. By flipping the order of this commutation sequence, the motor’s direction can be changed.

Methods to Change the Direction of Rotation

There are several methods to reverse the direction of a BLDC motor’s rotation, each suited to different scenarios depending on the hardware and control system available. Below are the most commonly used methods.

Swapping Any Two Stator Wires

One of the simplest methods to reverse the direction of a BLDC motor is to swap any two of the three stator wires. Brushless DC motors are typically powered by three-phase connections, and changing the phase sequence will cause the motor to spin in the opposite direction.

Procedure:

- Identify the three stator wires, often labeled U, V, and W.

- Swap any two of the stator wires. For example, you could swap U and V or U and W.

Example:

- Assume the stator wires are connected in the order U → V → W for clockwise rotation.

- Swapping U and V will change the order to V → U → W, which will result in counterclockwise rotation.

This method is straightforward but typically requires manual rewiring or the use of a switch to perform the phase swap automatically.

Using the Controller’s Direction Pin

Many BLDC motor controllers come with a dedicated pin or software setting that allows the user to change the direction of rotation without physically rewiring the stator connections. This pin is often labeled as “DIR” (for direction). When the direction pin is toggled (either by applying a high or low voltage or using a software command), the controller reverses the commutation sequence, which results in a change in the direction of rotation.

Procedure:

- Locate the direction control pin on your BLDC motor driver/controller.

- Apply the appropriate signal (high/low) to the direction pin based on the controller’s documentation.

- Alternatively, use software to send a command that reverses the motor direction.

Example Data:

- Input Voltage: 0-5V (digital signal)

- Direction Control Logic: A high signal (5V) may indicate forward rotation and a low signal (0V) may indicate reverse rotation.

This method provides more control over motor operation and is suitable for applications where automated control of motor direction is needed.

Reprogramming the Controller

In cases where more sophisticated control is required, the motor controller can be reprogrammed or configured to change the commutation sequence internally. This method is particularly useful when using advanced motor controllers that allow for customized control settings.

Procedure:

- Connect the controller to a programming interface (e.g., through a USB or serial connection).

- Access the control software or firmware settings.

- Change the settings to reverse the commutation sequence of the motor. This might involve setting the phase order to reverse.

Example:

A motor running in forward direction with a commutation sequence of (U, V, W) might have a default program like:

Phase 1: U+ V-

Phase 2: V+ W-

Phase 3: W+ U-

To reverse the rotation, reprogram the controller to:

Phase 1: U- V+

Phase 2: V- W+

Phase 3: W- U+

This method is often implemented in systems where the motor’s performance is closely monitored, and any changes to the direction need to be made through a software interface.

Reversing Hall Sensor Feedback

BLDC motors equipped with Hall sensors use the feedback from these sensors to determine rotor position and synchronize the commutation. Another way to alter the rotational direction is to reverse the signals from the Hall sensors. By switching the signal outputs of two Hall sensors, the controller will perceive the rotor as rotating in the opposite direction, thus reversing the motor’s movement.

Procedure:

- Identify the Hall sensor signal wires (usually three wires: Hall A, Hall B, Hall C).

- Swap any two of the signal wires to reverse the rotor position feedback.

This method is less common because it may interfere with precise motor control, but it can be effective in situations where the controller lacks a dedicated direction control pin or reprogrammable settings.

Using Dual H-Bridge Circuits

For advanced applications where precise control of direction and speed is required, an H-bridge circuit can be used to reverse the polarity of the voltage applied to the motor. This setup is more common for motors that require frequent and automated direction changes.

Procedure:

- The BLDC motor should be connected to an H-bridge circuit, which has four switches to regulate the current flowing through the motor’s windings.

- The H-bridge enables you to reverse the motor’s spin by altering the direction of current flow.

- Use a microcontroller or control system to send signals to the H-bridge circuit to reverse the motor’s direction as needed.

Example Data:

- Voltage Range: 12V-48V (depending on motor rating)

- Current Rating: 10A for typical BLDC motors used in robotics.

Impact of Changing Direction on Performance

When changing the direction of rotation, there are a few factors to consider:

1. Efficiency

Reversing the motor direction doesn’t significantly impact efficiency if done correctly. However, improper commutation or incorrect sensor feedback could lead to losses in efficiency and uneven torque generation.

2. Torque and Speed

The motor will maintain the same torque and speed characteristics when rotating in the opposite direction, provided the control signals and power supply remain constant. However, certain applications may require recalibration of control systems, particularly when using Hall sensors.

3. Wear and Tear

BLDC motors are designed to handle directional changes, but frequent reversals can increase wear on the rotor and bearings, especially in high-speed applications. It is crucial to ensure the motor is designed to handle frequent bidirectional movement if the application requires it.

Conclusion

Changing the direction of rotation of a brushless DC motor can be achieved in various ways depending on the hardware and control system available. The most straightforward method involves swapping two stator wires, while more advanced methods include using the controller’s direction pin, reprogramming the controller, adjusting Hall sensor feedback, or using an H-bridge circuit. Each method has its advantages and potential trade-offs, and the best choice depends on the application’s requirements for control, precision, and frequency of direction change.

Finally, brushless DC motor manufacturers offer a wide range of controllers and configurations to simplify the process of changing motor direction. With proper control methods, reversing the direction of a BLDC motor can be seamless, allowing for more versatile and adaptable motor operation across various industries.