What’s the DC servo motor?

A DC servo motor is a direct current (DC) motor that is coupled with a feedback mechanism to control its position, speed, and torque accurately. It forms part of a servo system, which includes a controller, a feedback device (such as an encoder or potentiometer), and the motor itself.

Working Principle

- Controller: Sends command signals to the motor driver based on the required position, speed, or torque.

- Motor Driver: Regulates the power supplied to the motor to align with the command signals from the controller.

- Feedback Device: Continuously monitors the motor’s actual position, speed, or torque and relays this data back to the controller.

- Error Signal: The controller compares the command signal with the feedback signal to generate an error signal, which is used to adjust the motor’s performance to reduce the error.

Key Components

- DC Motor: The core component that provides rotational motion.

- Encoder or Potentiometer: Used for feedback to measure the actual position or speed.

- Gearbox (optional): Used to increase torque and reduce speed for specific applications.

Types of DC Servo Motors:

- Brushed DC Servo Motors: These motors supply current to the motor windings through the use of brushes and a commutator. They have a more straightforward design and are typically less expensive, but because of brush wear, they need more care.

- Brushless DC Servo Motors: By eliminating the need for brushes through electronic communication, these motors offer increased efficiency, dependability, and reduced maintenance. Compared to brushed motors, they are usually more expensive and complex.

Characteristics

- Precision: DC servo motors offer precise control of position and speed.

- Speed-Torque Characteristics: They can provide high torque at low speeds, which benefits many precision applications.

- Control: Simple and effective control using PWM (Pulse Width Modulation) or other control methods.

Pros And Cons

Pros | Cons |

|

|

What’s the AC servo motor?

AC One kind of electric motor that produces precise and controlled motion is a servo motor, which runs on alternating current (AC). They are widely used in automation, robotics, CNC machinery, and various other industrial applications due to their high performance and reliability.

Working Principle

- Signal Input: The servo drive receives a control signal, which is typically supplied as a pulse width modulation (PWM) signal.

- Servo Drive: The servo drive processes the control signal and provides the appropriate AC voltage and current to the motor.

- Motor Rotation: The input signal causes the rotor of the AC servo motor to begin rotating.

- Feedback Loop: The servo drive receives real-time data regarding the position, speed, and direction of the motor via a feedback device, such as an encoder or resolver.

- Correction: The servo drive compares the feedback signal with the desired setpoint and makes necessary adjustments to ensure accurate motion control.

Key Components

- Stator: The motor’s stationary component that, when AC is applied, creates a revolving magnetic field.

- Rotor: The motor’s revolving component that tracks the stator’s rotating magnetic field.

- Encoder/Resolver: A feedback mechanism that gives the servo drive information about position, speed, and direction.

- Servo Drive: An electrical gadget that regulates the motor’s AC power supply in response to feedback and control signals.

- Controller: The central unit that sends control signals to the servo drive, often based on complex algorithms for precise motion control.

Types of AC Servo Motors

- Synchronous AC Servo Motors: These motors have a rotor that is magnetically locked to the rotating magnetic field, providing precise control and high efficiency.

- Asynchronous AC Servo Motors: These motors rely on induction to produce a rotating magnetic field in the rotor. They are less precise compared to synchronous motors but are more robust and cost-effective.

Characteristics

- High Precision: AC servo motors are perfect for applications needing exact motion because they provide fine control over position, speed, and torque.

- High Efficiency: They have high efficiency due to the synchronous nature of the motor’s operation.

- Fast Response: Suitable for dynamic applications, AC servo motors react to control inputs rapidly.

- Stable Operation: They provide smooth and stable operation even at low speeds.

- Feedback Control: The continuous feedback mechanism ensures accurate control and error correction.

Pros and Cons

Pros | Cons |

|

|

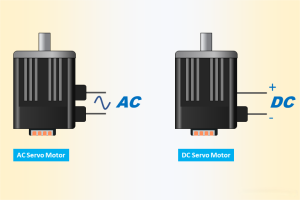

What’s the difference between DC servo motor and AC servo motor?

Power Source and Control

- DC Servo Motor: Runs on direct current (DC) and is managed by changing the motor’s input voltage or current. They typically have simpler control mechanisms, often utilizing analog signals for precise control.

- AC Servo Motor: Operates on alternating current (AC) and is controlled using more complex electronic devices, such as servo drives that modulate the AC signal. The control is usually digital, allowing for more sophisticated and precise motion control algorithms.

Performance Characteristics

- DC Servo Motor: Known for providing high torque at low speeds and excellent speed control. They are typically more efficient at lower speeds and are easier to control for simple, low-power applications. However, they can be less efficient at higher speeds and may require more maintenance due to brushes and commutators.

- AC Servo Motor: Provides enhanced efficiency and a wider speed range while operating faster. They provide consistent torque across a wide range of speeds and are more robust, requiring less maintenance as they do not have brushes.

Construction and Maintenance

- DC Servo Motor: Generally has a simpler construction with brushes and a commutator, which can wear out over time, leading to higher maintenance requirements. The construction allows for straightforward repairs and replacements.

- AC Servo Motor: Typically has a more complex construction with no brushes, resulting in less wear and tear and lower maintenance needs. The absence of brushes makes AC servo motors more reliable and durable, ideal for long-term use in demanding environments.

| Feature | DC Servo Motor | AC Servo Motor |

| Power Supply | Direct Current (DC) | Alternating Current (AC) |

| Control Mechanism | Typically simpler control circuitry | More complex control circuitry |

| Efficiency | Lower efficiency due to brushes and commutator | Higher efficiency, especially in synchronous types |

| Maintenance | Requires more maintenance due to brushes and commutator | Low maintenance, no brushes or commutator |

| Speed Control | Easier and more precise speed control | Speed control can be complex and less precise |

| Torque Characteristics | Provides high starting torque | Generally lower starting torque |

| Size and Weight | Generally smaller and lighter | Can be larger and heavier |

| Cost | Typically lower initial cost | Higher initial investment but cost-effective |

| Response Time | Faster response time | Slightly slower response time |

| Durability | Less durable due to wear and tear on brushes | More durable, longer lifespan |

| Heat Generation | More heat is generated due to brushes | Less heat generated |

| Example Applications | Toys, small robots, positioning systems | Industrial automation, CNC machines, robotics |

How do you choose the Right Servo Motor?

Selecting the appropriate servo motor requires taking into account a number of variables unique to the needs of the application. Here are some case studies that demonstrate the selecting process along with the important aspects to take into account.

Application Requirements

High-speed applications might need a different motor compared to high-torque, low-speed applications.

Load Characteristics: Understand the nature of the load, whether it’s constant, variable, or requires sudden changes in direction or speed.

Control System Compatibility

Verify that the servo motor and the control system in use are compatible. Check for the compatibility of the motor with the servo drive and controller.

Precision and Accuracy

Applications like CNC machining and robotics may require motors with high-resolution encoders for precise positioning.

Environmental Conditions

Consider the operating environment. Factors such as temperature, humidity, dust, and potential exposure to chemicals can influence the choice of motor.

Size and Weight

The physical size and weight of the servo motor can be critical, especially in applications with space constraints or weight limitations.

Power Supply

Determine the available power supply. Ensure the servo motor can operate efficiently within the given power constraints (AC or DC, voltage levels).

Cost and Maintenance

Consider the initial investment as the continuing maintenance requirements. AC servo motors generally have higher upfront costs but lower maintenance needs.

Feedback Mechanisms

Assess the type of feedback mechanism required (e.g., encoder, resolver) based on the application’s accuracy and precision needs.

Conclusion

A detailed grasp of the unique requirements and limitations of the application is necessary in order to select the appropriate servo motor. By carefully evaluating factors such as torque, speed, precision, environmental conditions, and compatibility, you can choose a servo motor that will provide optimal performance and reliability.